Our expertise

Our knowledge of plastic materials and our experience in designing certified ammunition containers enable us to offer products tailored to each specific requirement.

For 40 years, TIAG Industries established istelf as the leading company for designing and producing plastic ammunition containers for major European land armament partners.

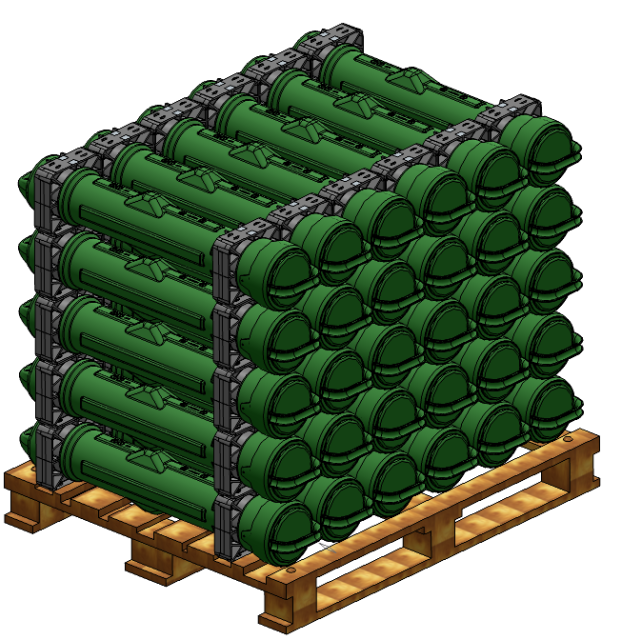

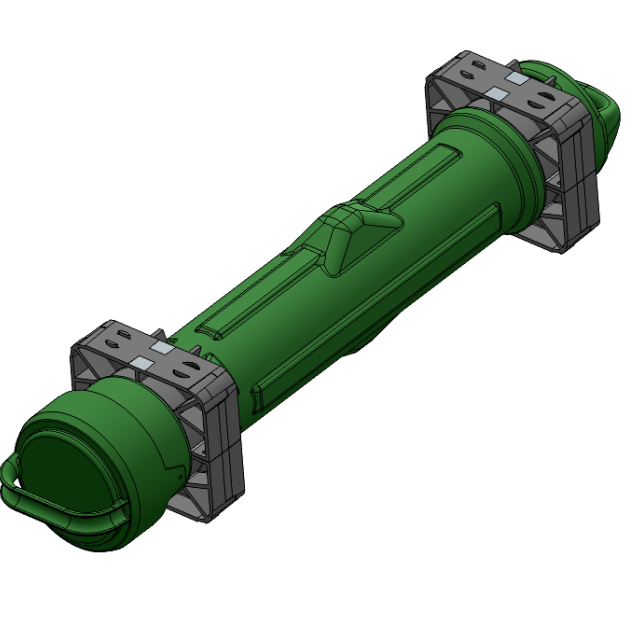

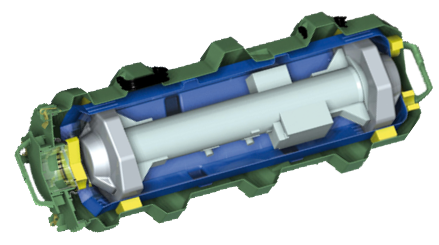

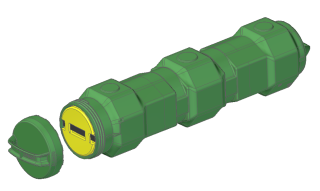

Based on its know-how about both plastic transformation techniques and military sector, TIAG has developed more than 30 containers adapted to many types of NATO ammunitions, such as propellant charges, missiles, mortars.

Now, TIAG proposes different ranges of ammunition containers, whether it is a 100% customized one for the ammunition, or a standard one, based on three-words motto : LIGHTWEIGHT, PERFORMANCE, COST-SAVINGS

Although continuing to propose a high quality-level of products, TIAG industries knows how to be agile by introducing innovative solutions and new ranges of containers, in addition of sustainable solutions. TIAG containers are reusable, recyclable, and aim to be composed with 30% of recycled plastic by the end of 2030 year.

This expertise has been rewarded in 2024, as TIAG won the Army Technology Excellence AWARDS 2024 for its last developed container : 120mm mortar standard container.

TIAG provides to its clients a rigourus follow-up, whether during technical phasis of the project, or during the operationnal phasis for delivery scheduling.

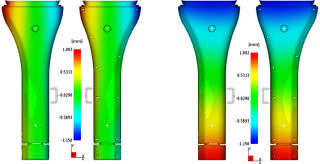

Our integrated Design Office is mobilized to support your project from the reception of your requirements to the specifications of your parts. TIAG Industries is indeed capable of designing container that fulfill NATO safety requirements, while respecting development planning.

It is during the project duration that TIAG team tests and suggests different raw material that will fit to the requirements without forgetting quality and aspect levels of containers. TIAG is also internally developping itself, regarding recyclability of material, but also by conceiving new ranges of standard containers coming soon.

Why choosing plastic containers ?

Knowing that each one of raw material used for containers, such as wood or steel, have their own advantages, plastic still is a relevant competitor.

• Excellent chemichal resistance

• High impact resistance

• Flexibility and elasticity

• Easy to process

• Lightweight

• Weather and UV resistance

• Good recyclability

• Cost effective